Experience

Relying on a senior managing team and a well-qualified operative group, WEGO Systems has the required practice to handle the constant challenges of the world class manufacturing.

Balance

Not focused in only one target, the company has analyzed case by case in order to obtain the perfect tune to among intrinsic quality, adequate delivery time and fair charging.

Flexibility

A modern concept of production managing allows us to be agile when modifications have to be made, even from project adaptations, production process and deadlines.

Commitment

The company values the legal engagements, just as well with clients, suppliers and employees.

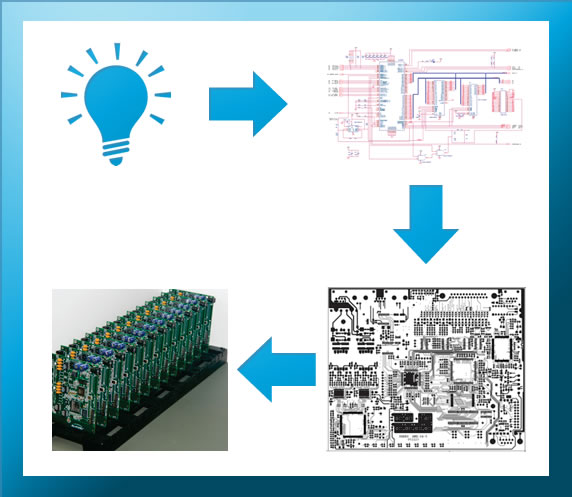

Electronic Products Manufacture Services

Our assignment is to promote trustable and innovative solutions, which can contribute to the continuous success of our clients’ companies.

ON SYSTEMS WEGO

WEGO Systems started operations in April 2013. The founding partners are highly qualified in the outsourced production market. From a sustainable start project, they are proud of the work done so far and desire to share this goal achievement with the customers.

Our mission is simple: To manufacture electronic products with quality. To this end, we have a policy of providing manufacturing services by continually improving processes and meeting the needs of all parties involved.

Our vision is to be among the 3 largest manufacturers of products in the southern region of Brazil by the year 2030. Our values are ethics, respect, innovation, and quality.

INFRASTRUCTURE

- 1000 m2 of production area

- SMT assembling line

- PTH assembling line (Pin Through Hole)

- Functional trial structure

- Mechanical integration structure

- Electronic product repairing structure (RMA)

- ESD strategy and Environment care for stocking

- Lead Free information upon request

PUBLICATIONS

Major actual limits of the manufacturing facility

This paper aims the orientation of some product architecture aspects in order to improve [...]

10 de novembro de 2016 / English